HJT清洗制绒设备

设备名称 Equipment Name

HJT清洗制绒设备 HJT Texturing Equipment

设备型号 Equipment Model

SC-CSZT12000E-24F

设备用途 Equipment Application

对高效太阳能电池异质结电池片进行制绒、清洗。

Used for texturing and cleaning of high efficiency Heterojunction solar cells.

工艺流程 Process Flow

酸洗→纯水清洗→去损伤→PSC1→纯水清洗→制绒→纯水清洗→纯水清洗→PSC1→纯水清洗→化学抛光(O3)→纯水清洗→SC2处理→纯水清洗→氢氟酸洗→纯水清洗→预脱水→烘干

Pre-cleaning→di water rinsing→saw damage removal→di water rinsing→texturing→di water rinsing→di water rinsing→psc1→di water rinsing→chemical polishing(o3)→di water rinsing→sc2 treatment→di water rinsing→hf cleaning→di water rinsing→hot water drying→warm air drying

技术特点 Features

1、兼容MES、UPS和RFID功能。

Suitable with MES, UPS and RFID function.

2、机械手分配合理,有效避免药液交叉污染和槽体反应超时。

Reasonable distribution of the lifts which can avoid cross-contamination of chemical liquid and reaction overtime of process bath effectively.

3、结构布局紧凑合理,酸性区域、碱性区域、高洁净区域采用隔断区分,设备占地空间小。

With compact and reasonable structural layout, acid area, alkaline area and high cleanness area separated by partition, with small footprint.

4、先进的双层槽结构,有效提高设备工艺产能。

Advanced double-layer bath structure improves the throughput effectively.

5、工艺槽体采用“定排定补”模式和“时间补液”模式相结合,有效延长药液使用寿命和减少换液周期。

Process baths combines the “feed & bleed” Mode with “Time Dosing” Mode, will extend the bath lift time and reduce the bath change period effectively.

6、补配液采用槽内与补液罐双磁致伸缩流量计线性检测,以及可调节气阀控流结构,有效保证初配时间和微量精补配液的精度。

Dosing and Make-up adopt linear detection of the double magnetostrictive flowmeter inside the bath and the dosing barrel, as well as adjustable valve flow control structure to ensure the time of initial make-up and accuracy of accurate dosing effectively.

7、所有与液体接触材料优化升级,避免材料使用杂质析出。

Optimize and upgrade all materials in contact with process liquid to avoid precipitation of impurities.

8、采用新全塑低温烘干技术,保证槽内洁净度和温度控制精度,提高制绒后少子寿命。

With the latest low-temperature drying technology to ensure the cleanliness and temperature control accuracy inside the bath, increase the minority carrier lifetime of solar cells.

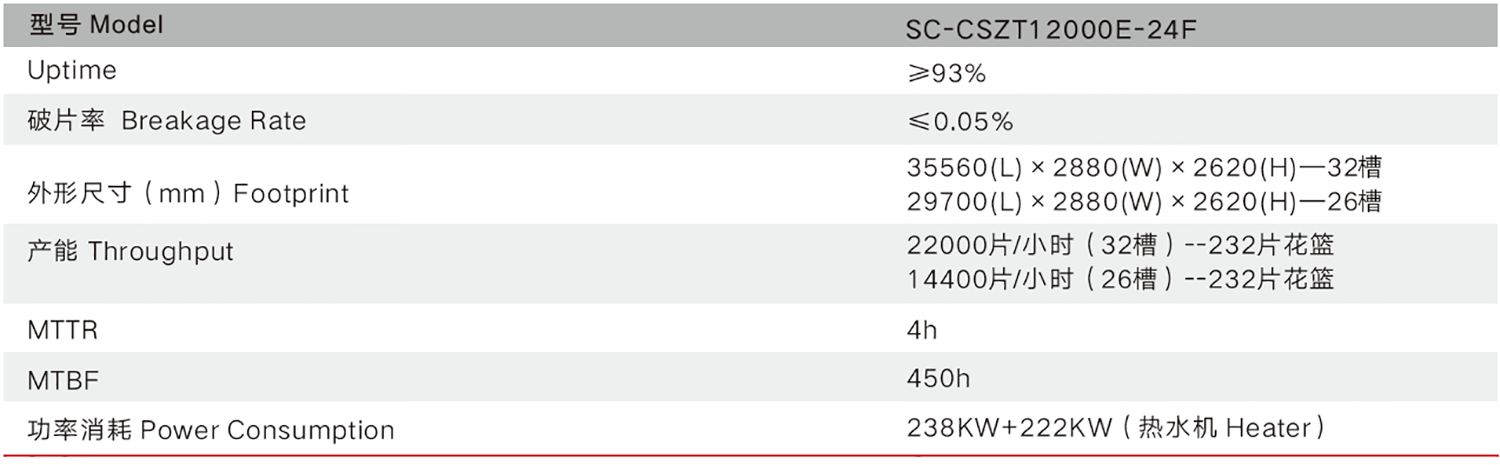

设备参数 Parameters