全自动石英舟装卸片机

全自动石英舟装卸片机

设备名称 Equipment Name

全自动石英舟装卸片机 Automatic Wafer Handling System for DOA Equipment

设备型号 Equipment Model

SYZ-VI-B

设备用途 Equipment Application

集装片和卸片一体,可从石英舟中把扩散后的硅片卸到片篮中,也可从片篮中将制绒后的硅片装入石英舟中。可在⼀个石英舟插槽中插⼊两片,实现单面扩散片工艺,也可在⼀个石英舟插槽中插入一片,实现双面扩散片工艺。采用装片与卸片可连续衔接⽅式,实现连续生产;也可单独装片或单独卸片。

Integrated wafer loading& unloading, unloading the wafers from the quartz boat to the cassette or loading the wafers from the cassette to the quartz boat. Available for double back-to-back wafers in one slot which realize single side diffusion or available for single wafer in a slot for double-side diffusion. With continuous wafer loading&unloading can guarantee the continuous production . Or be used only for wafer loading or unloading is also available.

技术特点 Features

1、采用进口六轴机械手装卸片,确保硅片取放高可靠性,降低硅片破碎率及划伤。

Six axis robot from world leading brand to load/unload wafers to ensure high reliability of wafer pick & place,and reduce the breakage rate and scratches on wafers.

2、HMI采用(IPC)工业计算机运行上位软件,通过网络通讯实现高速数据交互。

HMI adopts industrial computer (IPC) to run software and realize high-speed data interaction through network communication.

3、顶齿、吸盘重要零部件采用特殊加工工艺,极大降低顶齿印、吸盘印,顶齿、吸盘可实现快速更换。

Special processing technology is adopted for important parts such as combs and grippers which greatly reduce comb marks and gripper marks, and the comb and gripper can be replaced quickly.

4、可选配MES功能;可选配方阻检测模组;可选配AGV,自动化可实现一拖二配置,我司可根据客户需求定制个性化功能。

MES function/ sheet resistance detection module/ AGV system are optional; automation can be 1-by-2,functions can be customized according to customer needs.

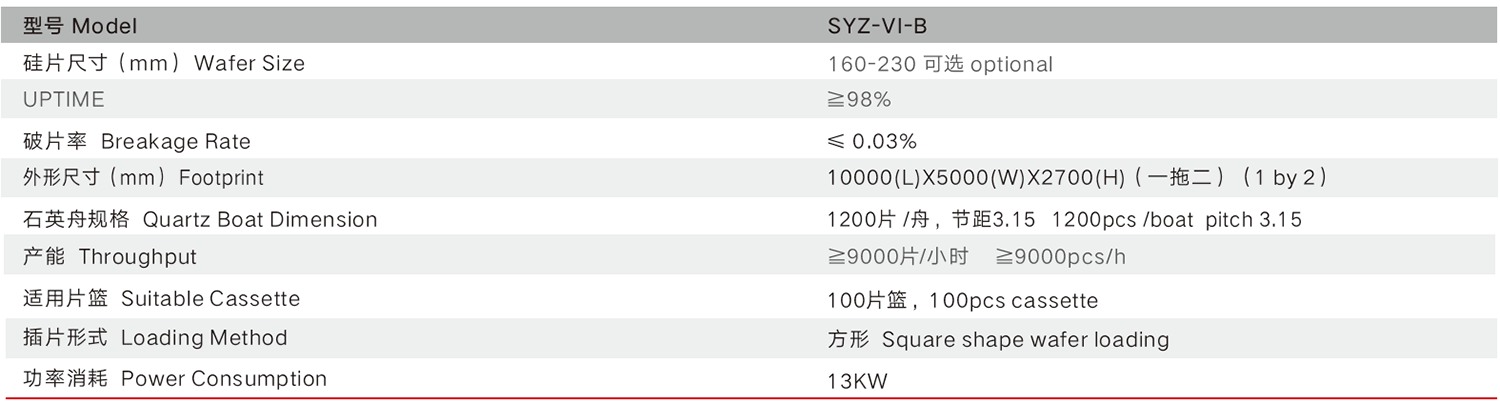

设备参数 Parameters